Garnet uses and mineral processing process

Garnet uses and mineral processing process

Blog Article

Garnet is a natural mineral composed of aluminum oxide and sodium aluminate. Garnet is not always red. Its color is determined by its chemical composition. For example, garnet composed of calcium is green, while garnet composed of iron, aluminum or manganese is red. Among them, blue garnet is the rarest, followed by green garnet. Garnet is widely distributed, and its main production areas are Australia, Brazil, South Africa and other countries.

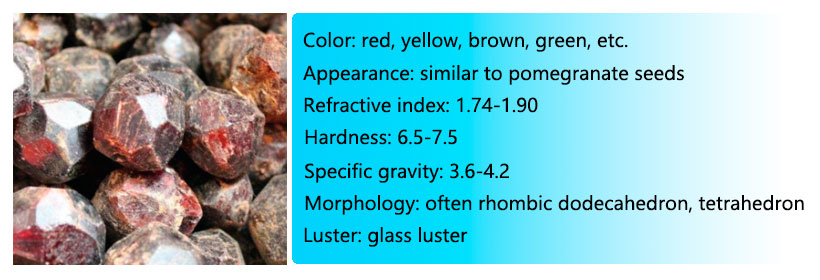

Garnet Properties

Garnet can be divided into six categories from the perspective of chemical composition, namely, iron aluminum garnet, rhodolite, andradite, spessartine, cinnamon stone, and calcium chrome garnet. Garnet has rich colors. Garnet containing chromium and iron elements presents purple-red, blood-red and brown-red; garnet containing iron and aluminum elements presents purple-red; garnet containing iron and magnesium elements presents light rose purple-red; garnet containing trace vanadium and chromium ions presents top-grade green;

Garnet belongs to island silicate in crystal structure. The common crystal forms of garnet are mostly rhombic dodecahedrons, but there are also hexadecahedrons, tetrahedrons and polyhedrons, and the crystal faces have growth lines. In addition, garnet has a glassy luster and is transparent or slightly transparent. The hardness is between 6.5-7.5, and the specific gravity is between 3.6-4.2. It has the characteristics of high hardness, good wear resistance and corrosion resistance.

Uses of garnet

Jewelry industry: Garnet has a beautiful appearance and unique color, and is often processed into various accessories such as bracelets and bracelets. Garnet has rich and colorful colors and is very popular in the jewelry market.

Industrial field: Garnet is processed into powder and used in industry for processing and manufacturing of ships, cars, airplanes, electronics, high-speed rail, cement, ceramics, leather, etc. In addition, garnet sand can also be used for sandblasting and rust removal, which has the advantages of safety, efficiency and environmental protection.

Health care: Garnet can also be used to improve blood circulation, strengthen the body, relieve fatigue, etc. It is believed to be able to enhance immunity, improve anemia, promote wound healing and relieve muscle soreness. In addition, trace elements such as iron and calcium contained in garnet help dilate blood vessels, increase blood flow and accelerate blood circulation.

Environmental protection industry: Garnet can also be used for grinding, polishing and sandblasting to remove rust. It has the advantages of no free silicon, wear resistance, acid and alkali resistance and other environmental protection standards, and gradually replaced traditional abrasives.

Garnet beneficiation process

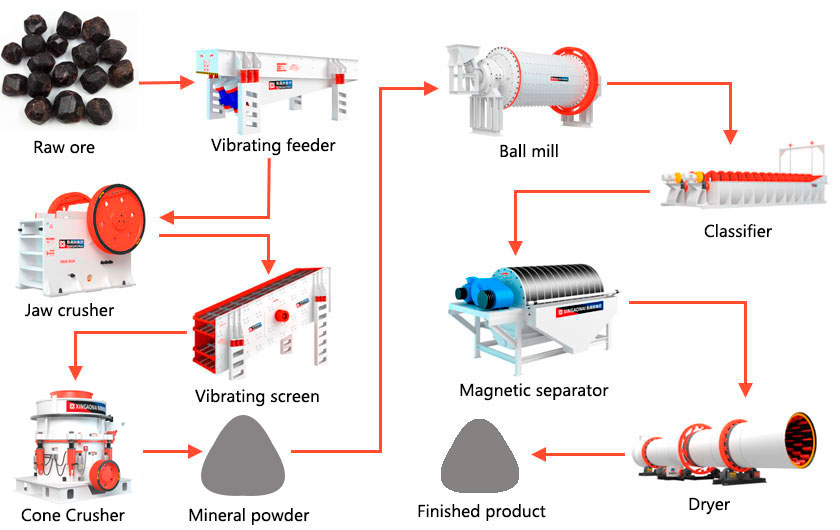

Crushing equipment: jaw crusher, Cone Crusher.

Grinding and grading equipment: ball mill, spiral classifier.

Sorting equipment: garnet magnetic separator, feeder, screening machine, conveyor.

Garnet beneficiation is divided into the following two processes:

Crushing process: The garnet raw stone is relatively large and needs to be crushed by jaw crusher, cone crusher and other crushing equipment. The particle size of the crushed material needs to meet the grinding requirements of the ball mill, generally below 30mm.

Ore dressing process: The crushed materials are sent to the ball mill for grinding. The ground materials pass through the classifier to remove the dirt in the materials. At the same time, the materials are screened and sent to the silo. The vibrating feeder then evenly feeds the materials in the silo to the trapezoidal jig and large particle jig. The selected concentrates and tailings are dehydrated and stored separately.

Author:[Xingaonai] Report this page